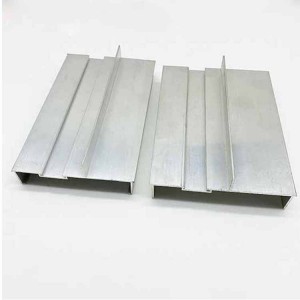

Anodized Aluminium Profile

Product Detail

Product Tags

The advantages of Anodized Aluminium Profile

1.Light and energy saving

2.Various colors for choice

3.Easy to fabricate and clean

Anodized Aluminium Profile is after the extrusion process of industrial aluminum profiles, they need to undergo anodizing surface treatment, which is often referred to as anodizing, and then a protective film is formed on the surface of the profile. This protective film is also often referred to as an anodizing film. The thickness of the anodizing film needs to reach a certain standard in order to play a protective role.

Here we introduce some advantages of Anodized Aluminium Profile:

1. Anti-corrosion. The stroke of the anodizing film can cut off the contact between the air and the aluminum profile, thereby preventing corrosion.

2. Anti-static. In addition to anti-corrosion, the anodizing film can also prevent static electricity. Therefore, many anti-static workbenches, clean sheds, etc. are made of communication aluminum profiles, which can reduce the adhesion of dust and easy to clean.

3. Beautiful and generous. the surface of Anodized Aluminium Profile is as bright as new and has a long service life. Used to make equipment hoods, protective fences, etc., beautiful and elegant. And there are many colors to choose from, such as champagne, imitation steel, etc., which reflects the decorative effect of aluminum profiles.

4. Health and safety. Anodized Aluminium Profile is not necessary to apply paint in the later stage, no gas such as formaldehyde is generated, health and safety, and low maintenance cost.

| Product | Anodized Aluminium Profile | |

| Aluminum Alloy | 6063, 6063A, 6061, 6463, 6463A, 6060, 6005, 6082, etc. | |

| Temper | T4, T5, T6 | |

| Quality Standard | China National Standard GB/T 5237-2008 (High Precision Class), China National Standard GB/T 6892-2006(High Precision Class) | |

| Quality Certificate | ISO 9001:2015, ISO 14001:2015, CQM Certification | |

| Application | Aluminum window and door frames, curtain walls, railings, furniture decoration, heat sinks, industrial parts, railway vehicles, etc. | |

| Surface Treatment | Anodizing: Silver, champagne, bronze, black, gold, titanium, imitating steel, etc. | |

| Electrophoresis: Sliver, champagne, black, golden, titanium, etc. | ||

| Power coating: RAL normal color, or customize customer color samples | ||

| Polishing: Mechanical polishing or chemical polishing | ||

| Wood Imitation: Normal wooden color or customized wooden color | ||

| Fluorocarbon Coating: AkzoNoble color or customize customer color samples | ||

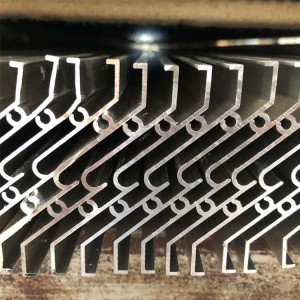

| Deep Processing Ability | Drilling, punching, bending, CNC, aluminium alloy profile fabrication, Precise cutting etc. | |

| MOQ | 500 kgs to 3,000 kgs | |

| Packing Details | Protection film and hot shrink plastic film / EPE foam packing / brown paper packing / wooden packing / Metal pallet or depend on clients special requirement. | |

| Payment Term | 1) T/T: 30% of total value as deposit by T/T within 3 days to confirm the order, and the balance to be paid by T/T before loading the container. | |

| 2) L/C: 30% of total value as deposit to be paid by T/T within 3 days to confirm the order, and the balance to be paid by L/C at sight after loading the container. | ||

| 3) Big order: Pay 30% of total value as deposit by T/T within 3 day to confirm the order, and the balance to be paid by T/T after delivery against the copy of B/L. | ||

| Shipping Methods | Ocean shipment, air shipment, land transportation and multi-transportation, etc. | |